Gunderson

Double Stack Construction - Part 1

You know the show Friends, Sex in the City and how they all go. Well, this guy don’t. He is in the basement working on new projects. I don’t have time for all that crap when there are trains to build. I am like the guy in the Ford tuck commercial….

At some point in time, I decided after the gondola project, I wanted to build a double stack car. Also, I wanted to learn AutoCad and design the car on screen. The goal was that at the end of the project, I would have a complete set of drawings for once.

The first part of the project, as with any project, is to get the necessary information to build the car. I liked the 48-foot stand-alone Gunderson well car. This particular car seems to be very elusive. I went from Illinois to Wyoming to New Mexico and back and never seen a one. The cars I found in a yard were behind barbed wire fences. The ones I seen on the trains were going 50 miles per hour. I contacted Gunderson via e-mail. They were only a little helpful sending me a color pamphlet with a few dimensions. I ask them for more information - you may as well ask the pentagon for plans for the latest weapons.

I go 'what is the big deal'. The car is 10 years old. The other companies already have them. Anyway, as luck would have it, I found one on a sidetrack all by itself. I had a tape measure, pencil, paper and camera complete with film. Before I was done, I had the information I was looking for.

There are some long

side pieces required in the building of this car. The sides are not very

high so they have to be strong. Basically, I had to build the car exactly

like the prototype or it would be bent in the middle the first time some

decided to see how strong it was and step in the middle of it. And you

know they will…

I found a local steel dealer that bent the side part from 11-gauge steel. They are tricky bends since none are right angles but they have to form a right angle when welded together. This is a case where you have to know the Boss of the place or at least the Secretary who really runs the place. I was lucky; the parts came back as pre drawing.

It still took a full size paper and pencil layout on the drawing board to make sure the trucks fit and the car didn’t drag the ground, that the couplers would be the correct height and everything looked like it was in the correct place. Next step was to analyze the photos and sketch out what the parts would look like and where they would go.

Finally, I made it to the computer with some sketches and dimensions. As luck would have it. I recently acquired a new helper at work - a good-looking 21-year-old blond that knows AutoCad. My prayers were answered. Not only that, she is a good instructor and patient. You know you have to show us old guys things 15 times or we won’t remember it.

I am happy to report

that after about 4 weeks of hard work, I have become fairly proficient

at making my own drawings with just a little help now and then. To date

I have completed about 10 drawings and produced the parts you see in the

photos. I plan to use 3D AutoCAD to assemble the parts on screen before

the project is completed.

|

|

11/30/2001

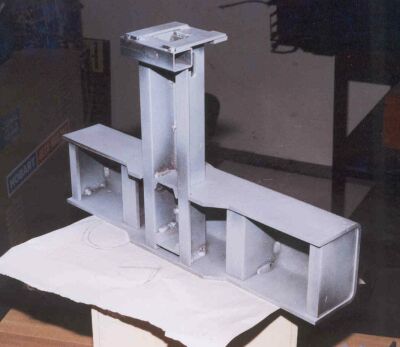

- Here are the Gunderson end assemblies now welded together.

This is the bare bones end structure of the car pretty much as it is in

the prototype.

|

|

Here's photo of the parts that will soon be welded into sides for the

car.

|

Now here are a couple photos of the main car structure clamped together for a test fit.

Click on Photos for larger View

|

|

|