Cylindrical Grain

Car Project Update - Part 4

click

on images for larger view

Note: This edition

of the Cylindrical Hopper car article was

written by a guest editor, instead of Lee as usual.

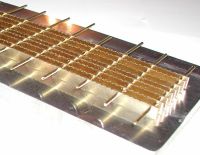

One of the newest

details Lee is working on for this car is the walkways. As seen in the

photos below, they are being assembled in brass. The block of aluminum

the grate is resting on will soon contain many 5/32" aluminum pegs

to lock the spacing of the pieces in place. The grid parts will be bound

using an advanced soldering process. Once the grid parts are soldered

together, the extra rod lengths will be cut away from the sides and finished

smooth.

|

How do you make eight

*identical* pieces of grate stock so the final grate is straight and square?

The photos below show the fixture Lee built to hold the pieces together

while the machining is completed. There are two steps being completed

on this fixture; on the top section, the brass bars are having their 'dimples'

created with a CNC program. Buried on the side of the fixture, there is

a fresh set of bars that are ready to be drilled through the guide holes

with another CNC program.

|

Another key detail for this

car are the top hatches. Lee has got these just about ready to paint.

Yes, they work. You can open the hatch to access the cap screws that hold

these hatches to the top of the car.

|

Now to the bottom of the car. Lee has made a number of intricate parts for the discharge gates as seen in the photos below. Each car will have four of these gates

|

Here's Lee contemplating the last few details to be completed on this assembly.

|

Below left: you can see the discharge gates in place on the the chutes.

Below right: Here's the top side of the chutes.

|

Just for grins - Here's what can happen if a

bottle of Gorilla Glue gets away from you.

- Won't ever lose that knife -

|

One last detail shot; in this photo you can see the newly installed brake lever bracket.

|

Stay tuned for more details on the completion of this car.