|

A Precision Steel

Car Flat Car with the "Wright" Touch

click

on images for larger view

Looking at that

box of greasy parts is somewhat intimidating. Kind of makes one think

that maybe, in this case, I better read the instructions first. The good

news is that the instructions are mostly pictures. It’s a guy thing.

I won’t purchase a book unless it has more pictures than text.

I took their advice

and assembled the whole thing as best I could using their box lid for

a work bench. This was just a dry assembly to get an idea of where all

the parts go. Next I am thinking, this would be great if I could just

glue it together. No problem…however that is not the case.

After that dry assembly,

I let it set and looked at it from time to time for a month or two. I

just wasn’t quite comfortable just starting to weld without my own

plan of attack. I could see a lot of grinding in my future if I had overlooked

something and a flat car that was not flat. In a few areas, I deviated

from Precision Steel Car's assembly instructions to make this car more

compatible with the way I build my cars and to add some additional details.

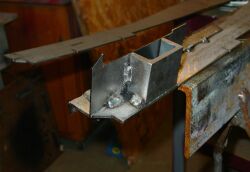

The first task was

to hold the main center parts together and keep them straight.

I solved this problem by welding a piece of 2” channel on top of

the coupler plate. It strengthens the plate and adds sides to use as a

clamp. I cut and milled these parts exactly 1.75 to match the plate and

located it so as not to be in the way of the coupler pin to be installed

later.

A long time ago when

constructing my first car, I determined that the couplers should be somewhat

adjustable up and down. I have used a standard way of doing this on every

car since and it work very well, as well as giving the car a prototype

appearance.

To this end I used

some 1/8” X 5/8” angle to make a bolt flange outside the center

spars.

As you can see in the photos, this give me about 1/8” more vertical

clearance in the coupler pocket. I machined about .050 off the inside

of the angle so that I did not lose all of the horizontal clearance.

With the angle welded

onto the center frames right and left and extending ¼” past

the center pin box I set about clamping up the center frame. As exemplified

by the photos, aluminum blocks were machines also to 1.750 and used as

spacers behind the coupler pocket. This is important because welding will

draw the sides of the center frame in or out depending on where you place

the welds. We want these parts to stay parallel. Temporarily install the

frame end (as in step 4 of the instruction book) as an additional aid.

Do not weld it on yet.

When I was sure that

the parts were aligned properly the first welds were made. Note that I

am using a piece of 4” angle that is very straight to clamp the parts

to for welding.

Also, I did not follow

the instructions at this point for two reasons. The goal was to keep the

center straight and parallel. In the kit I received, the four main cross

braces were made from 1/8” material and tended to remain straight.

The bolster cross pieces and end pieces were made from 18 gauge and, with

the deep cut, could possibly be bent. PSC is in the process of changing

the end pieces to be made from 1/8" material.

Page [1] [2]

[3] [4]

>>

|